The global artificial stone market is experiencing unprecedented growth, projected to expand at 6% CAGR through 2034, with modern gray variations leading demand across commercial and residential sectors. For architects, developers, and procurement managers navigating the complex landscape of engineered stone suppliers, selecting the right modern gray artificial stone factory requires understanding manufacturing standards, regional production capabilities, and emerging design trends. This comprehensive guide provides actionable strategies for evaluating manufacturers, negotiating bulk purchases, and ensuring quality compliance—whether you're sourcing for luxury hotel developments, high-end residential projects, or custom furniture manufacturing. Unlike generic product guides, this resource focuses specifically on supplier selection criteria, certification verification, and cost optimization tactics essential for B2B buyers in 2026's competitive marketplace.

Understanding Modern Gray Artificial Stone

Modern gray artificial stone represents the convergence of advanced manufacturing technology and timeless aesthetic appeal, offering a sophisticated alternative to natural stone for demanding commercial and residential applications. The material's composition typically consists of 93% natural quartz aggregates combined with 7% polymer resins and carefully calibrated pigments. This precise formulation delivers exceptional durability while maintaining the visual authenticity that designers and property owners demand.

The manufacturing process begins with crushing raw materials into fine particles, followed by mixing with resins and pigments in industrial-scale mixers. The mixture then undergoes vibro-compression under vacuum conditions—a critical step that eliminates air pockets and ensures structural integrity throughout each slab. After molding, slabs cure in climate-controlled chambers at elevated temperatures for 24-48 hours, followed by grinding, polishing, and edge-profiling to achieve the desired finish.

Gray continues dominating the 2026 market due to its remarkable versatility across design styles, from minimalist modern to industrial chic. However, the specific shade preferences are evolving significantly. Warm gray finishes incorporating subtle beige undertones are replacing the cool grays that dominated the previous decade, reflecting broader trends toward inviting, comfortable spaces. Concrete matte textures with rough, industrial finishes appeal particularly to commercial developers creating urban-inspired hospitality environments.

The distinction between natural marble, engineered marble, and quartz-based artificial stone matters critically when selecting suppliers. Natural marble offers unique veining but requires intensive maintenance and lacks consistency across slabs. Engineered marble uses marble dust with resin binders, providing better uniformity but less durability than quartz-based products. Modern gray artificial stone manufactured with quartz aggregates delivers superior performance characteristics including stain resistance, heat tolerance, and minimal maintenance requirements—making it ideal for high-traffic commercial installations, luxury residential kitchens, and custom furniture applications.

2026 Gray Artificial Stone Trends

Steel gray variations featuring industrial textures and metallic flecks are gaining significant traction among commercial developers seeking to create distinctive urban atmospheres in restaurants, hotels, and corporate offices. These surfaces often incorporate dynamic veining patterns and brushed finishes that mimic raw concrete or oxidized metal, delivering a masculine, contemporary edge while maintaining engineered stone's performance advantages. This trend aligns with the growing demand for materials that combine aesthetic boldness with practical durability in high-traffic environments.

Concrete matte warm gray finishes represent perhaps the most significant shift in the 2026 market, as designers move away from the sterile cool grays that dominated interiors for nearly a decade. These warmer neutrals—incorporating taupe and sand tones—create softer, more inviting spaces that complement the wood cabinetry and natural textures trending in both residential and commercial projects. Leading modern gray artificial stone manufacturers now offer extensive collections featuring these transitional hues, recognizing that projects increasingly demand materials that bridge contemporary and traditional design languages.

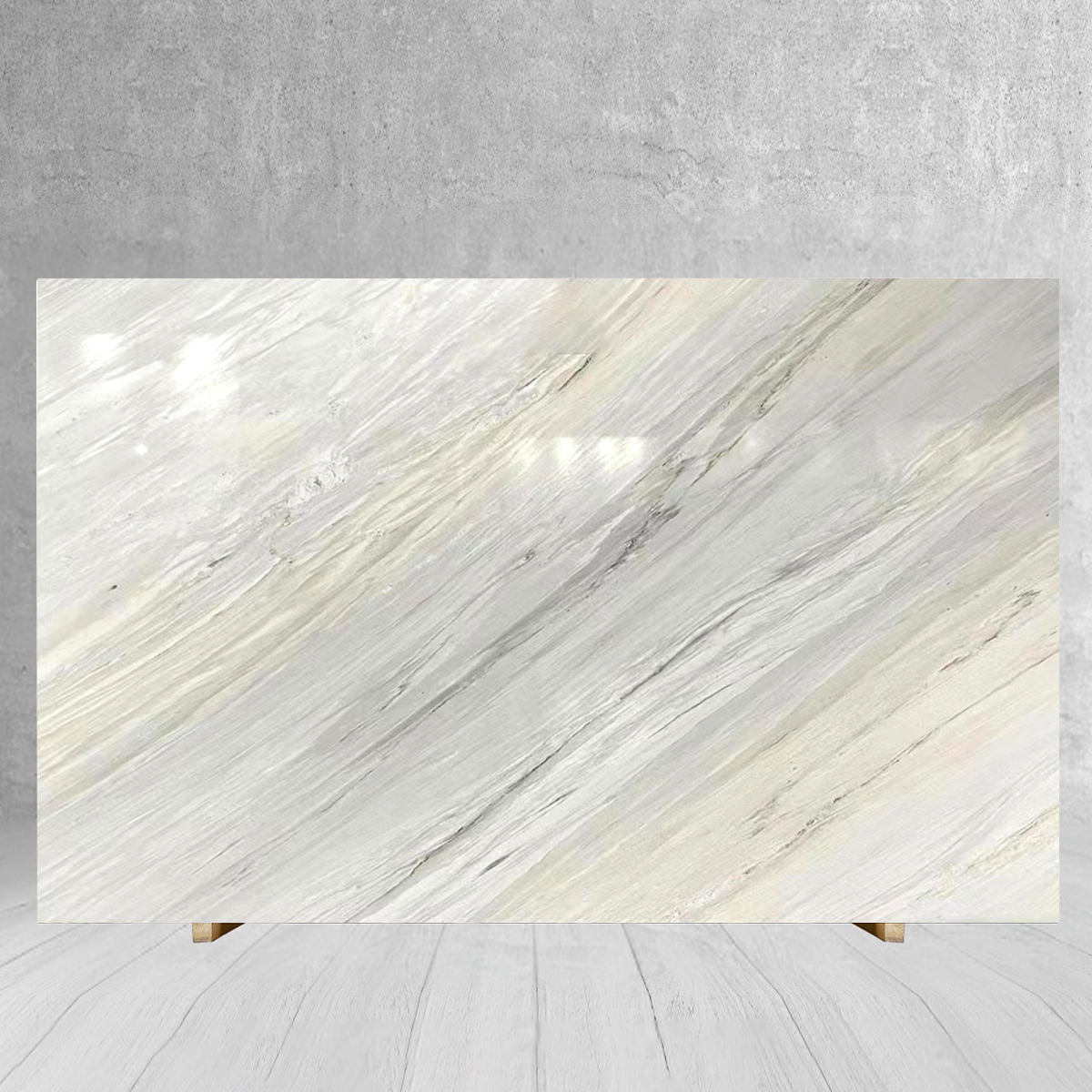

Gray veining patterns on white bases continue their remarkable popularity, particularly calacatta-style designs that replicate the drama of Italian marble without the maintenance challenges. The 2026 iterations feature more nuanced veining with golden hour tones and warm undertones, departing from the stark black-on-white patterns of previous years. This evolution reflects sophisticated buyers' desire for statement pieces that feel authentic rather than formulaic, pushing manufacturers to develop more varied and naturalistic veining patterns.

Smart stone applications incorporating anti-bacterial coatings and advanced sealing systems are transforming artificial stone from purely decorative material into functional technology. Healthcare facilities and hospitality properties increasingly specify these enhanced surfaces, which offer antimicrobial protection without compromising aesthetic appeal. Advanced polymer-modified additives improve strength, reduce water absorption, and enhance freeze-thaw resistance for both interior and exterior applications. This intersection of natural stone aesthetics with modern technology addresses practical performance demands while maintaining the sophisticated appearance that specifiers require.

Top Artificial Stone Manufacturing Regions

China dominates global artificial stone production, with advanced manufacturing facilities concentrated primarily in Guangdong and Fujian provinces offering comprehensive capabilities from raw material processing through finished slab fabrication. These modern gray artificial stone manufacturers leverage sophisticated production lines, abundant quarry resources, and skilled workforces to deliver competitive pricing alongside increasingly high quality standards. Major B2B platforms including Alibaba, Made-in-China, and Global Sources provide access to hundreds of verified Chinese suppliers, though careful vetting remains essential.

Chinese manufacturers have invested heavily in automation technology and intelligent manufacturing systems, significantly improving production efficiency while reducing labor costs and scrap rates. Leading facilities now produce large volumes of premium quartz slabs using advanced technology that ensures consistency across production batches. The customization capabilities available from top-tier Chinese factories—including bespoke color matching, specialized finishes, and custom dimensions—make them particularly attractive for large commercial projects requiring specific aesthetic requirements.

European manufacturers like TechniStone set quality benchmarks through rigorous environmental certifications including EPD (Environmental Product Declaration) that evaluates impacts throughout the entire product lifecycle. These producers focus on sustainability credentials, water conservation, and low-impact production methods that appeal to projects requiring verified environmental compliance. CE marking, mandatory for stone products sold in the European Union, confirms conformity with EU construction product regulations covering safety, health, and environmental standards. While European sources typically command premium pricing, the comprehensive documentation and established quality systems justify the investment for projects with stringent compliance requirements.

North American producers increasingly focus on Greenguard-certified products that meet rigorous indoor emissions standards, addressing growing demand from commercial developers and institutional buyers prioritizing occupant health. This certification requires testing against more than 10,000 chemicals with stringent limits on chemical emissions during manufacturing—crucial for LEED-certified projects and health-conscious developments. The movement toward zero-silica and low-silica engineered stone, once concentrated in Australia and New Zealand, has expanded throughout North America and Europe, with commercial projects proactively seeking compliant surfaces ahead of anticipated regulatory changes.

Emerging markets in Turkey and India offer competitive pricing advantages for bulk orders, particularly for projects with less stringent certification requirements. These manufacturers serve growing domestic construction markets while building export capabilities, making them worth evaluating for cost-sensitive projects. However, buyers should conduct thorough due diligence regarding quality consistency, compliance documentation, and export experience before committing to large orders from less-established markets.

Quality Standards and Certifications

ISO 9001 certification for quality management systems represents the foundational standard that reputable modern gray artificial stone factories should maintain, ensuring consistent production quality through documented processes and continuous improvement methodologies. This certification demonstrates that manufacturers have implemented clear quality management systems applicable across all working processes and personnel, providing confidence in batch-to-batch consistency. When evaluating suppliers, request current ISO 9001 certificates and verify validity through official registries rather than accepting documentation at face value.

ISO 14001 environmental management certification indicates commitment to reducing negative environmental impacts through sustainable manufacturing practices. Manufacturers holding this certification must meet established standards demonstrating attention to environmental issues including water conservation, energy efficiency, and waste reduction. For projects requiring sustainability credentials or pursuing green building certifications, ISO 14001 represents a minimum threshold, with more progressive manufacturers also obtaining EPD certifications that provide detailed environmental impact data.

ASTM standards define technical requirements widely used in North American markets, with several specifications particularly relevant for artificial stone manufacture and selection. ASTM C97 establishes test methods for absorption and bulk density of dimension stone, predicting material behavior under humidity and freeze-thaw cycles. ASTM C170 defines compressive strength testing, while ASTM C880 and C99 measure flexural strength and modulus of rupture—critical for load-bearing applications and cantilevered installations. Request test reports documenting compliance with relevant ASTM standards, particularly for projects in North America where these specifications often appear in architectural specifications.

Greenguard certification verifies low chemical emissions meeting stringent indoor air quality standards, with particularly high credibility in international markets and recognition by sustainable construction organizations. Products achieving Greenguard certification undergo rigorous testing protocols, making them suitable for health-conscious developments, schools, healthcare facilities, and LEED projects. As commercial buyers increasingly prioritize occupant health and wellness, this certification provides meaningful differentiation for artificial stone manufacturers targeting premium market segments.

CE marking requirements for European Union markets confirm that stone products meet CPR (Construction Product Regulations) covering safety, health, and environmental standards. Products sold in EU markets must display CE marking, making this essential for manufacturers targeting European export markets. The certification process involves third-party testing and ongoing quality surveillance, providing additional quality assurance beyond manufacturer claims.

NSC 373 (Natural Stone Sustainability Standard) represents a voluntary certification focused specifically on environmental, social, and economic sustainability in stone production. This standard addresses ethical quarrying practices, fair labor conditions, and community benefits—increasingly important considerations for projects with comprehensive sustainability mandates. While less common than ISO certifications, NSC 373 provides meaningful differentiation for manufacturers committed to responsible sourcing beyond basic environmental compliance.

Evaluating Artificial Stone Manufacturers

Production capacity and lead times directly impact project schedules and supply continuity, making these critical evaluation criteria for any modern gray artificial stone factory. Assess whether manufacturers can handle your project volume while maintaining quality standards, and verify their typical lead times for standard versus custom orders. Manufacturers with insufficient capacity may struggle to meet deadlines or maintain consistency across large orders, while those with excess capacity relative to their order book may offer more competitive pricing and flexibility. Request information about current production schedules, seasonal capacity fluctuations, and their ability to accommodate rush orders if project timelines compress.

Quality control processes separate professional manufacturers from unreliable suppliers, with batch traceability and mock-up installation options providing crucial verification before committing to full orders. Reputable suppliers implement quality checks at every production stage, testing hardness, density, water absorption, and colorfastness to ensure products meet industry standards. Request details about their QC protocols, including what percentage of production undergoes testing and what happens with materials that fail inspection. The willingness to provide mock-up panels for visual and quality approval—showing actual color, finish, and book-matching patterns—demonstrates confidence in product consistency.

Technical specifications require careful evaluation across multiple performance dimensions that affect long-term durability and suitability for intended applications. Key parameters include:

- Density & Water Absorption (ASTM C97): Lower water absorption rates (typically under 0.5% for quality artificial stone) predict better performance in humid environments and freeze-thaw conditions

- Flexural Strength & Modulus of Rupture (ASTM C880/C99): Critical for countertop applications and any installation involving cantilevers or unsupported spans

- Abrasion Resistance (ASTM C1353): Essential for flooring and high-traffic surface applications where wear patterns would become visible over time

- Chemical Resistance:** Particularly important for kitchen and bathroom applications where household cleaners, acids, and alkaline substances contact surfaces regularly

Request comprehensive technical data sheets documenting these specifications, and consider third-party testing for high-value projects.

Sample evaluation procedures should follow a systematic approach before placing bulk orders. Always order samples—paying for materials and shipping demonstrates serious buyer intent and represents minimal investment relative to potential issues with full orders. Evaluate samples for color consistency against your specifications, finish quality including polish depth and surface texture, and dimensional accuracy. Measure thickness at multiple points and compare against purchase order specifications. If your project requires multiple slabs, request samples from the same production lot to assess potential variation, as even engineered stone can show slight differences between batches. Retain samples with corresponding invoices and batch numbers for warranty validation and future reorders.

Export experience and compliance documentation become crucial for international purchases, where shipping complications, customs issues, or inadequate documentation can derail projects and inflate costs. Evaluate manufacturers' track record shipping to your specific country, as experienced exporters understand local import regulations, required certifications, and documentation requirements. Request references from buyers in your market and verify their experience with that supplier. Confirm the manufacturer maintains necessary export licenses, provides comprehensive compliance documentation, and offers post-sale support for international customers.

Sourcing Strategies for Bulk Buyers

B2B platforms including Alibaba, Made-in-China, and Global Sources provide efficient starting points for modern gray artificial stone manufacturer research, offering searchable databases with supplier profiles, product ranges, and buyer reviews. These platforms allow filtering by production capacity, certification status, export experience, and other relevant criteria. However, treat online platforms as research tools rather than complete vetting mechanisms—verify claims independently and conduct deeper due diligence before committing to large orders. Look specifically for suppliers with Trade Assurance or Gold Supplier status, transaction histories, and detailed company profiles showing years in business and export markets served.

Attending the Canton Fair and specialized stone industry trade shows offers irreplaceable value for face-to-face supplier meetings, product sample inspection, and relationship building that online research cannot replicate. These events allow you to evaluate multiple manufacturers efficiently, compare product quality directly, and assess professional capabilities through in-person interactions. Trade shows also provide opportunities to discover emerging suppliers not yet prominent on online platforms and to negotiate preliminary terms that can be formalized after the event. Schedule supplier meetings in advance and prepare specific questions about production capabilities, quality systems, and customization options to maximize your time at these events.

Negotiating volume discounts represents a standard practice for developers, contractors, and furniture manufacturers placing bulk orders, with suppliers typically offering favorable pricing based on order volume. Contact potential suppliers with detailed requirements including desired quantities, timeline expectations, and any customization needs. Structure negotiations around total project volume rather than individual shipments—manufacturers offer better terms when confident in substantial overall business. Consider ordering fewer varieties, dimensions, and finishes per container, as suppliers often provide better deals for less complex orders. For ongoing needs, explore partnership arrangements with staggered deliveries that secure volume pricing while managing inventory costs and cash flow.

The choice between working with authorized dealers versus direct factory sourcing involves trade-offs requiring careful consideration. Direct factory relationships typically offer lower per-unit costs and access to full customization capabilities, making them attractive for large projects with specific requirements. However, dealers provide valuable services including domestic inventory, faster delivery for smaller quantities, technical support, and simplified returns—benefits that may justify their markup. Established dealers also maintain relationships with multiple manufacturers, providing access to diverse products and competitive options. For initial purchases or projects with uncertain specifications, dealers reduce risk, while experienced buyers with clear requirements and sufficient volume often benefit from direct factory relationships.

Requesting full material composition disclosure and third-party test reports protects against substandard products and verifies manufacturer claims. Reputable manufacturers willingly provide detailed information about quartz content, resin types, pigments, and additives used in their formulations. Third-party testing by independent laboratories offers unbiased verification of performance characteristics, particularly important for high-value projects or when working with unfamiliar suppliers. Request certification documents directly from issuing bodies when possible, or verify certificate numbers through official registries to confirm authenticity. Manufacturers reluctant to provide comprehensive technical documentation or verifiable certifications should raise immediate concerns about quality and transparency.

Cost Considerations and Pricing

Price ranges for artificial stone slabs vary dramatically from budget-friendly options starting around $40-50 per square meter for basic gray finishes to premium engineered surfaces exceeding $150 per square meter for specialized textures, custom colors, or designer collections. Standard modern gray artificial stone slabs from established Chinese manufacturers typically fall in the $60-80 per square meter range for bulk orders, while European producers command $100-200 per square meter reflecting higher labor costs, environmental compliance, and brand premium. Understanding where your project falls on this spectrum helps establish realistic budgets and identify suppliers matching your quality-cost positioning.

Hidden costs beyond quoted slab prices can substantially impact total project economics, requiring careful evaluation during sourcing decisions. International freight charges vary significantly based on shipping method (sea versus air), destination, and fuel surcharges—typically adding $5-15 per square meter for container shipments from Asia to North American or European ports. Insurance for cargo, customs clearance agent fees, and import duties (which vary by country and product classification) collectively add another 10-25% to landed costs. Factor in warehousing, domestic transportation, and any inspection or testing fees when calculating true cost comparisons between suppliers.

Multiple factors affect pricing beyond base material costs, creating opportunities for optimization through informed specification decisions. Slab thickness represents a primary cost driver, with standard 3cm slabs commanding premium pricing over 2cm options, though thinner materials may require additional support structures offsetting material savings. Finish types range from basic polished surfaces at standard pricing to honed, leathered, or textured finishes requiring additional processing and corresponding cost increases of 15-30%. Color complexity significantly impacts pricing—solid grays with minimal veining cost substantially less than intricate patterns requiring precise pigment control and longer production times. Order volume creates leverage, with per-unit costs dropping substantially as quantities increase, making consolidated purchasing across multiple project phases economically attractive.

Payment terms and negotiation strategies require careful navigation, particularly for first-time bulk purchases from international suppliers. Standard terms typically involve 30% deposit upon order confirmation, with balance due before shipment or against copy of shipping documents. For larger orders or ongoing relationships, negotiate staggered payments tied to production milestones—deposit, mid-production inspection, and final payment after quality approval but before shipping. Letter of credit arrangements through banks provide protection for both parties but add administrative costs and complexity. Build clear penalty clauses for delivery delays or quality failures into contracts, while also understanding that unreasonably aggressive payment terms may limit supplier options or increase quoted prices reflecting payment risk.

Total cost of ownership extends beyond purchase and installation to include maintenance requirements and expected lifespan. Quality artificial stone slabs require minimal ongoing maintenance compared to natural stone—typically just routine cleaning without sealing, polishing, or specialized treatments. This low maintenance burden delivers significant lifecycle savings for commercial applications where labor costs for upkeep would otherwise accumulate substantially over 10-15 year periods. However, lower-quality products may stain, scratch, or degrade more rapidly, requiring premature replacement that negates initial cost savings. Evaluate warranties (typically 10-15 years for quality manufacturers) and maintenance requirements when comparing options, as products with higher upfront costs but superior durability often deliver better long-term value.

Applications for Modern Gray Artificial Stone

Kitchen countertops and bathroom vanities in luxury residential projects represent the largest application segment for modern gray artificial stone, driven by the material's combination of aesthetic appeal, durability, and low maintenance. The non-porous surface resists staining from common kitchen substances including wine, coffee, and oils while tolerating heat exposure from cookware without requiring hot pads. In 2026, over 60% of new home buyers prefer high-quality engineered surfaces for these critical spaces, with gray variations offering timeless sophistication that complements diverse cabinet finishes and design styles. The consistent appearance across large installations—avoiding the variation challenges of natural stone—ensures cohesive aesthetics particularly important in open-plan homes where kitchen surfaces remain highly visible.

Customized artificial marble furniture including dining tables and coffee tables has emerged as a rapidly growing application, particularly for hospitality and high-end residential markets seeking distinctive statement pieces. Modern gray tones provide neutral foundations that ground interior schemes while allowing colorful accessories and artwork to take center stage. Manufacturers now offer specialized services for furniture fabrication including integrated sink basins, embedded tech components for charging stations, and custom edge profiles that transform functional surfaces into sculptural elements. The material's superior resistance to scratches and stains compared to natural marble makes it practical for high-use furniture applications where maintenance requirements would otherwise limit natural stone viability.

Commercial applications in hotels, restaurants, and corporate office spaces leverage artificial stone's performance characteristics alongside its design versatility. Reception desks, bar tops, and communal work surfaces in these high-traffic environments require materials that maintain appearance despite intensive use—artificial stone's non-porous composition and stain resistance make it ideal for these demanding applications. Healthcare facilities increasingly specify engineered stone for its hygiene benefits, as the non-porous surface prevents bacterial growth and simplifies cleaning protocols critical for infection control. Recent innovations in antimicrobial formulations have accelerated adoption in hospitals by 28% year-over-year, addressing both aesthetic and functional requirements in medical environments.

Flooring and wall cladding applications for high-traffic areas require materials balancing durability with aesthetic appeal—engineered stone's exceptional abrasion resistance makes it suitable for commercial lobbies, retail spaces, and institutional corridors where natural marble would wear prematurely. Large-format slabs and ultra-thin panels expand design possibilities, allowing dramatic floor-to-ceiling installations with minimal grout lines. The material's lightweight profile compared to natural stone reduces structural load requirements, making it practical for high-rise applications and renovation projects where weight limitations constrain material options.

Specialty uses in engineered marble furniture for the hospitality industry extend beyond standard countertops to include custom headboards, bathroom vanity units, decorative wall panels, and sculptural design elements. Hotels seeking distinctive identities increasingly request custom veining patterns or embedded designs in gray artificial stone that align with their brand aesthetic. The material's processing capabilities—cutting, routing, thermoforming, and edge profiling—enable complex custom fabrication that would be prohibitively expensive or technically impossible with natural stone. This flexibility positions modern gray artificial stone as both a practical surfacing material and a design medium for creating signature elements in luxury hospitality environments.

Working With Manufacturers: Best Practices

Establishing clear communication channels and comprehensive technical specification sheets prevents misunderstandings that lead to unsatisfactory deliveries and costly corrections. Provide manufacturers with detailed drawings including accurate dimensions of all surface areas, location of sinks and appliances, desired edge profiles, and backsplash requirements. Create specification sheets documenting exact color references (ideally with physical samples or manufacturer's existing product codes), finish type, thickness requirements, and any special processing needs. Clarify quality standards including acceptable variation tolerances for color, dimension, and finish—what you consider defects versus normal variation. Establish dedicated contact points on both sides and agree on communication protocols including response time expectations and preferred channels (email, messaging apps, video calls) to ensure continuity throughout the project.

Requesting samples with payment demonstrates serious buyer commitment and represents essential due diligence before committing to bulk orders. Suppliers view buyers willing to pay for samples and shipping costs as serious prospects rather than casual inquirers, resulting in better responsiveness and attention. Samples allow verification that manufacturers can actually produce the quality, color, and finish you require before financial and timeline commitments lock you into a potentially problematic supplier relationship. For large projects requiring multiple slabs, request samples from the intended production lot to assess batch consistency. Document sample approval in writing with photographs and specific references to approved characteristics, creating objective standards against which to evaluate final deliveries.

Conducting factory audits or requesting third-party inspection reports provides crucial verification of manufacturers' actual capabilities versus their marketing claims. On-site visits allow assessment of production equipment modernity, facility cleanliness and organization, worker training and safety practices, and quality control implementation. If personal visits aren't feasible, retain third-party inspection companies to conduct factory audits and provide detailed reports including photographs, certification verification, and capability assessment. These inspections should occur both during supplier selection and at critical production milestones for large orders, ensuring consistent quality throughout manufacturing. The investment in professional inspection services—typically a few hundred dollars—provides insurance against far more costly quality failures.

Understanding MOQ (minimum order quantity) requirements and production timeline expectations prevents unrealistic project assumptions and allows proper planning. Most modern gray artificial stone factories establish MOQs based on production efficiency—often one full container (approximately 600-800 square meters) for standard products, with higher minimums for custom colors or specifications. Clarify whether quoted lead times represent production duration only or include raw material procurement, and factor in international shipping (typically 4-6 weeks for sea freight) when establishing project schedules. Seasonal capacity variations affect lead times, with Chinese New Year, summer holidays, and peak construction seasons potentially extending normal production schedules by several weeks. Build appropriate buffers into critical path schedules and establish clear milestone dates with penalties for delays in purchase agreements.

Negotiating warranty terms, return policies, and liability coverage for damaged goods protects your investment and establishes clear recourse if issues arise. Quality manufacturers typically offer 10-15 year warranties for residential applications covering manufacturing defects, though carefully review what's actually covered versus excluded. Distinguish between defects attributable to manufacturing versus installation errors, as most warranties exclude damage from improper installation, abuse, or failure to follow care instructions. Establish clear processes for handling damaged goods during shipping—who bears replacement costs, freight charges, and timeline delays. For international purchases, understand jurisdiction for dispute resolution and practical feasibility of pursuing claims across borders, potentially making escrow arrangements or third-party inspection protocols worthwhile for high-value orders.

Building long-term relationships with consistent quality and pricing advantages benefits both parties, creating mutual incentives for reliability and problem-solving. Suppliers prioritize repeat customers with predictable order volumes, offering preferential pricing, production scheduling, and technical support. Consistent partnerships allow manufacturers to better understand your quality standards and preferences, reducing specification time and quality disputes on subsequent orders. For buyers, established relationships provide supply security, streamlined ordering processes, and greater flexibility during schedule changes or specification modifications. Approach supplier selection as identifying long-term partners rather than simply executing transactions, even if initial orders start small as relationship testing.

Conclusion

Successfully sourcing modern gray artificial stone requires balancing aesthetic requirements, performance specifications, budget constraints, and supplier reliability—a complex evaluation best approached through systematic methodology rather than price-focused shortcuts. The manufacturers and regions discussed in this guide represent diverse options spanning quality tiers, certification levels, and pricing structures suitable for projects ranging from cost-sensitive commercial developments to ultra-luxury residential installations. The 2026 market trends toward warmer gray tones, smart surface technologies, and sustainability certifications are reshaping product offerings, creating opportunities for informed buyers while potentially complicating decisions for those unfamiliar with current developments.

The certification standards and evaluation criteria outlined here provide frameworks for objectively assessing manufacturers beyond marketing claims, while the sourcing strategies and negotiation tactics offer practical tools for optimizing both quality and cost outcomes. Whether you're an architect specifying materials for a landmark hospitality project, a developer managing procurement for a residential tower, or a contractor establishing supplier relationships for ongoing renovation work, the investment in thorough supplier evaluation and relationship building delivers returns through reduced risk, improved quality, and long-term cost advantages.

For comprehensive artificial stone solutions backed by global sourcing capabilities, quality certifications, and expert technical support, explore Future Stone Group's engineered stone collections featuring modern gray variations suitable for luxury residential, commercial, and hospitality applications.

FAQ

What is the difference between artificial stone and engineered marble?

Artificial stone and engineered marble differ primarily in their base composition and resulting performance characteristics. Artificial stone typically uses 93% natural quartz aggregates as its primary component, combined with polymer resins and pigments, creating an extremely hard, non-porous surface with superior stain and scratch resistance. Engineered marble, by contrast, uses marble dust or crushed marble as its aggregate base mixed with resin binders, producing a surface that more closely mimics natural marble's appearance but offers somewhat less durability than quartz-based products.

The manufacturing processes share similarities including mixing, compression, and curing, but quartz-based artificial stone typically requires higher compression pressures and longer curing times due to the harder aggregate material. For applications prioritizing maximum durability such as commercial countertops or high-traffic surfaces, quartz-based artificial stone generally provides better long-term performance, while engineered marble suits projects where aesthetic authenticity to natural marble takes priority over absolute durability.

How do I verify a manufacturer's quality certifications?

Verifying manufacturer certifications requires checking validity through official registries rather than accepting provided documentation at face value. For ISO certificates (9001, 14001), request the certificate number and issuing body, then verify directly with the certification organization through their online registries or contact information—legitimate certificates can always be independently confirmed. Check that certificates remain current, as certifications require periodic renewal, and expired certificates indicate lapsed quality systems.

Request third-party test reports from independent laboratories documenting compliance with relevant standards like ASTM specifications, and verify these laboratories' accreditation status. For specialized certifications like Greenguard or NSC 373, contact the certifying organization directly to confirm the manufacturer's listing in their database of certified companies. Consider hiring third-party inspection companies to conduct factory audits that verify actual implementation of quality systems rather than just paper compliance. This investment in verification prevents costly problems with substandard materials that could jeopardize project schedules and budgets.

What are typical lead times for bulk artificial stone orders?

Production timelines for bulk artificial stone orders typically range from 20-45 days depending on order volume, customization complexity, current factory capacity, and seasonal factors. Standard products in established colors with straightforward specifications generally require shorter lead times (20-30 days), while custom colors, special finishes, or unique dimensions extend production schedules toward the upper range. These timeframes represent manufacturing duration only—not total delivery time.

International shipping adds substantial additional time, with sea freight from Asian manufacturers to North American or European destinations typically requiring 4-6 weeks from port to port, plus customs clearance and domestic transportation. For complete planning, factor in sample approval time before production begins, potential delays during peak seasons (Chinese New Year, summer holidays, major construction seasons), and inspection/quality control periods if specified. Total timeline from order confirmation to delivery often spans 12-16 weeks for international purchases, making early procurement initiation critical for projects with fixed completion deadlines.

Can manufacturers customize gray shades for specific projects?

Most established modern gray artificial stone manufacturers offer custom color matching capabilities for projects requiring specific shades beyond their standard collections. The customization process typically begins with providing physical samples, color codes (Pantone, RAL), or detailed photographs of desired shades, followed by the manufacturer creating test samples for approval. Multiple iteration rounds may be necessary to achieve precise matches, particularly for complex colors with multiple undertones or veining patterns.

Minimum order quantity requirements for custom colors typically exceed standard products—often requiring at least one full container (600-800 square meters) or more depending on the manufacturer. Additional costs for custom color development, including formulation time and test batches, typically add 15-30% to base pricing, though this premium diminishes with larger order volumes. Lead times extend by 2-4 weeks compared to standard products due to color development and approval processes. The sample approval workflow should include written documentation with photographs and retention of approved physical samples as quality standards against which to evaluate production runs.

What warranty should I expect from reputable manufacturers?

Reputable artificial stone manufacturers typically provide 10-15 year warranties for residential applications, though warranty terms vary significantly regarding what's actually covered. Standard warranties cover manufacturing defects including delamination, excessive porosity, structural failures, and significant color variation beyond normal tolerance ranges. However, most warranties explicitly exclude damage from improper installation, physical abuse, exposure to harsh chemicals beyond normal household use, and outdoor applications unless specifically rated for exterior use.

Review warranty documentation carefully to understand claim procedures, required documentation (often including original purchase invoices, installation records, and maintenance logs), and whether coverage is prorated or full replacement. Commercial application warranties typically offer shorter coverage periods (5-10 years) reflecting higher use intensity. Warranty transferability matters for residential projects, as non-transferable warranties lose value if properties sell before warranty expiration. For international purchases, clarify jurisdiction for warranty claims and practical procedures for obtaining replacements, as logistical complexity can render warranties theoretically valid but practically unusable. Documentation requirements typically include photographs of defects, purchase records, and proof of proper installation and maintenance.