Natural stone remains one of architecture's most enduring materials, yet its extraction carries environmental responsibilities that architects, developers, and designers increasingly scrutinize. With over 11 billion tons of stone quarried globally each year, the industry faces mounting pressure to demonstrate that beauty and environmental stewardship can coexist.

Future Stone Group addresses these concerns through operational transparency and alignment with evolving sustainability frameworks. Operating three production facilities with 50,000m² monthly processing capacity and direct quarry partnerships in Italy's Carrara region and Turkey's Afyon province, the company demonstrates how vertical integration enables environmental oversight from extraction through final delivery.

The Environmental Reality of Stone Extraction

Stone quarrying fundamentally alters landscapes. Traditional operations disrupt ecosystems, consume substantial water volumes, and generate carbon emissions through energy-intensive extraction and long-distance transportation. These impacts explain why environmentally conscious specifiers demand documented proof of responsible sourcing rather than marketing claims.

Water management presents the most immediate environmental challenge. Cutting and processing operations historically discharged sediment-laden water into local watersheds, affecting aquatic ecosystems and community water sources. Modern closed-loop systems now achieve 85-90% water recovery through settling tanks, filtration, and dewatering technologies. Filter presses remove water from stone slurry, creating dry waste "cakes" that reduce disposal volume by over 90% while recovering additional water for continuous reuse.

Habitat disruption extends beyond the quarry footprint. Unmanaged extraction fragments wildlife corridors and eliminates native vegetation. Progressive operations address this through controlled extraction zones that limit disturbance areas and concurrent rehabilitation—restoring completed sections while active quarrying continues elsewhere. This approach reduces total disturbed area at any given time and allows early vegetation establishment that stabilizes soils more effectively than attempting site-wide revegetation after decades of exposure.

Carbon emissions from heavy machinery, transportation, and processing contribute to stone's environmental footprint. Regional sourcing within 500 miles of project sites eliminates long-distance shipping emissions—a significant consideration given stone's weight. Future Stone Group's established logistics networks serving USA (34% of inquiries), Australia (22%), and Canada (12%) reflect market demand for materials that balance aesthetic requirements with transportation efficiency.

Industry Standards for Verifiable Sustainability

The ANSI/NSC 373 Sustainable Production of Natural Dimension Stone standard provides third-party verification of environmental and social responsibility across eight performance areas: water management, site management, land reclamation, corporate governance, energy and carbon, waste management, human health and safety, and innovation. Third-party auditors from NSF International conduct yearly monitoring and on-site recertification every three years, creating ongoing accountability rather than one-time certification.

The standard uses a point-based system where producers earn Bronze, Silver, Gold, or Platinum certification levels based on measurable criteria. Products from certified operations carry the "Certified Genuine Stone®" logo, providing visual confirmation of sustainable sourcing for specification documents.

Chain of Custody (COC) certification extends verification throughout supply chains, tracking stone from quarry through each processing step to final installation. Each organization handling material must achieve COC certification for stone to retain certified status, preventing "greenwashing" where uncertified material might be mislabeled during distribution.

Future Stone Group's ISO 9001:2015 certification and CE marking for EU exports establish quality management frameworks that align with these evolving industry standards. For projects pursuing LEED certification—particularly those in North American and European markets where environmental transparency increasingly influences procurement decisions—documented sustainability credentials become specification requirements rather than optional enhancements.

Technical Approaches to Reduced Environmental Impact

Modern quarrying technology reduces environmental impact through several mechanisms. Water recycling systems with automated variable-speed pumps optimize consumption based on actual processing needs rather than running continuously at maximum capacity. This operational discipline, combined with closed-loop treatment, virtually eliminates freshwater withdrawal after initial system filling.

Energy-efficient extraction equipment operates with less power per unit of stone produced while generating less dust that would otherwise require water-intensive suppression. Renewable energy integration—solar panel installations and wind turbines powering processing facilities—reduces dependence on fossil fuels, particularly for equipment that can operate intermittently based on renewable generation availability.

Waste reduction through material repurposing transforms quarrying from purely extractive to resource-maximizing. Stone offcuts and remnants previously destined for landfills now become raw materials for mosaic tiles, construction aggregate, and other value-added products. This "zero waste" approach reduces both landfill burden and the need to quarry additional material.

Future Stone Group's technical team references Natural Stone Institute guidelines when advising on installation standards, maintenance protocols, and material selection for different climates and seismic zones. This integration of sustainability considerations into specification support helps architects and contractors reduce risk of costly on-site corrections and premature performance issues.

Quarry Rehabilitation: Long-Term Environmental Stewardship

Progressive rehabilitation restores completed quarry sections during active operations rather than deferring all restoration to mine closure. This approach spreads rehabilitation costs over the quarry's operational life, maintains smaller total disturbed areas, and enables early vegetation establishment.

Typical progressive rehabilitation includes backfilling exhausted pits with overburden, reshaping contours to blend with surrounding topography, redistributing preserved topsoil, and beginning revegetation as sections stabilize. Comprehensive rehabilitation plans developed before extraction begins establish clear targets for post-quarry land use based on existing environmental conditions including soil quality, hydrology, native vegetation types, wildlife habitats, and cultural heritage sites.

Successful rehabilitation transforms former quarries into productive landscapes through reforestation with native species, creation of wetlands or reservoirs providing habitat and water management functions, conversion to recreational areas serving local communities, and agricultural use where soil conditions permit. Long-term monitoring and adaptive management allow operators to adjust techniques based on vegetation survival rates, soil stability, and wildlife return.

Lifecycle Analysis: Natural Stone vs. Engineered Alternatives

Durability fundamentally changes sustainability calculations. Natural stone properly installed and maintained lasts for centuries without replacement, while engineered alternatives typically require replacement every 10-30 years. A building facade using natural stone may serve 200+ years, while engineered alternatives might require 5-10 replacements over the same period, multiplying their lifecycle carbon impact.

Natural stone carries lower embodied carbon than most engineered materials across full lifecycle analysis. While extraction and transportation require energy, stone processing avoids the energy-intensive chemical manufacturing that engineered surfaces demand. Engineered stone, ceramic tile, and concrete require high-temperature kilns, synthetic resins, and chemical additives that substantially increase embodied carbon.

Natural stone's end-of-life advantages include 100% recyclability and repurposing in new applications without additional quarrying. The material is inherently biodegradable and contains no synthetic resins that limit recyclability—a consideration increasingly important for projects pursuing circular economy principles.

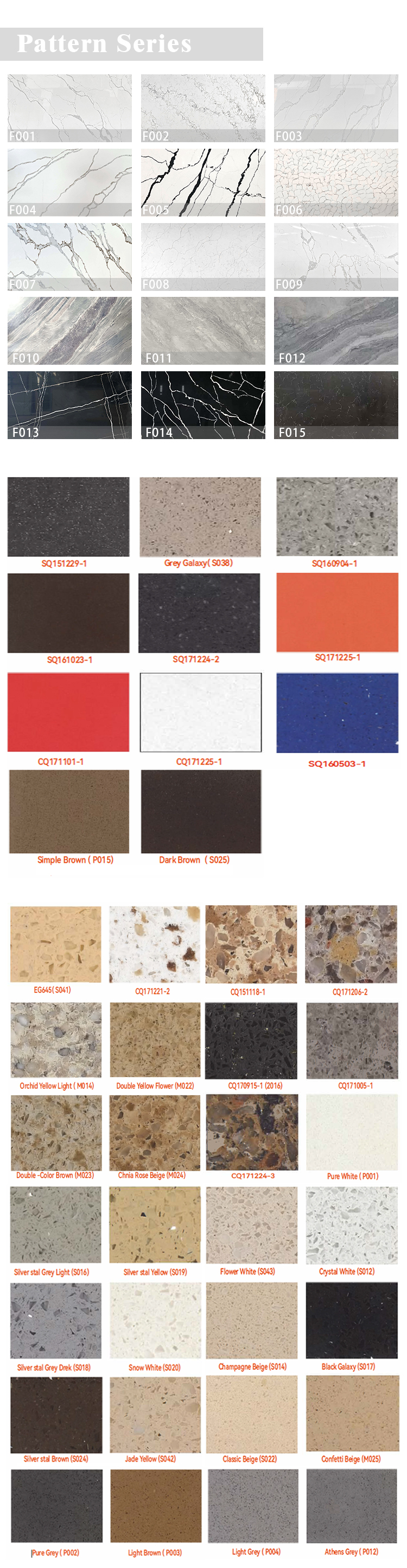

Future Stone Group's portfolio spanning natural marble, granite, travertine, onyx, and quartzite alongside engineered stone and quartz solutions enables specifiers to select materials optimized for each application's specific performance requirements and environmental priorities. This flexibility allows high-visibility zones to receive carefully selected natural stone while secondary areas utilize more economical but compatible engineered materials.

LEED Contributions and Green Building Integration

LEED (Leadership in Energy and Environmental Design) certification recognizes buildings meeting high sustainability standards. Natural stone contributes to multiple credit categories when properly documented.

Materials & Resources credits reward materials with Environmental Product Declarations (EPDs) documenting lifecycle impacts, responsible extraction certifications, and reduced embodied carbon compared to alternatives. Regional Materials credits apply when stone is extracted, processed, and manufactured within 500 miles of project sites for minimum 10% of total materials cost. Sustainable Sites credits become available when stone with high Solar Reflectance Index (SRI) values reduces heat island effects in paving and roofing applications. Indoor Environmental Quality credits recognize materials that don't emit volatile organic compounds (VOCs)—an inherent characteristic of natural stone.

The cumulative effect helps projects achieve LEED Silver, Gold, or Platinum certification while meeting client expectations for both sustainability and aesthetic quality. For Future Stone Group projects including Four Seasons hotel developments and custom residential work in high-end markets, these certifications provide documented proof that luxury and environmental responsibility coexist.

Supply Chain Transparency and Ethical Labor

Environmental sustainability cannot be separated from social responsibility in ethical sourcing. ANSI/NSC 373 certification evaluates human health and safety practices, corporate governance, and community engagement as core sustainability components. Certified operations must demonstrate worker protection programs exceeding regulatory minimums, fair labor practices including appropriate wages and working conditions, and community consultation processes addressing local concerns about quarry operations.

Ethical sourcing extends to supporting local economies through employment, infrastructure development, and post-closure land uses benefiting communities where quarries operate. Future Stone Group's 17-year operational history (established 2008) and relationships with over 1,000 satisfied clients reflect sustained commitment to quality and reliability that depends on stable, ethical supply chains.

Technical Performance Standards That Enable Sustainability

Material selection based on measurable technical properties—not just visual appearance—enables sustainable specifications that avoid premature failure and replacement. Compressive strength above 50 MPa indicates marble suitable for high-load flooring and sidewalks. Flexural strength determines appropriateness for thinner tiles and facade panels subjected to bending loads. Water absorption below 0.6% by weight guides selection for wet areas, exterior conditions, and freeze-thaw exposure.

Abrasion resistance proves essential in airports, metro stations, and commercial spaces where rolling luggage and maintenance equipment concentrate wear. Future Stone Group's portfolio organization by technical criteria allows design teams to match each area's mechanical and environmental demands to appropriate materials, optimizing performance and lifecycle cost simultaneously.

Format standardization—600×600mm, 600×1200mm, or similar modular dimensions—maximizes yield from quarry blocks and minimizes off-cut waste across large installations. Wholesale buyers and project fabricators document 20-30% savings through standardized grids versus mixed custom sizes, primarily from reduced waste and more efficient production.

Engineered Stone: Complementary Role in Sustainable Projects

Engineered marble and quartz-based surfaces blend natural stone aggregates with resin binders to create products with lower porosity, consistent mechanical properties, and controlled color patterns. These materials support green-building objectives by reducing quarry waste, offering more energy-efficient production processes, and enabling thinner, lighter components that lower structural demands.

Some manufacturers introduce bio-based resins and low-emission additives helping projects meet indoor air quality and environmental certification targets, particularly in European markets with stringent regulations. For high-hygiene zones like commercial kitchens and healthcare facilities, engineered stone's non-porous surface eliminates bacteria harbor points while requiring less maintenance than natural alternatives.

Future Stone Group manufactures engineered marble and quartz solutions alongside natural stone ranges, allowing project teams to replace traditional materials in appropriate zones with prefabricated, standardized components. This approach proves particularly effective in large hotel or apartment programs requiring thousands of identical bathrooms, countertops, and stair units installed with minimal waste and rework.

Practical Implementation: From Specification to Maintenance

Sustainable stone specifications succeed through robust substrates, correct bedding materials, adequate movement joints, and strict adhesive coverage control, all aligned with recognized industry standards. Thin-set installations require keying mortar into substrates, combing with notched trowels, and pressing tiles for 100% contact in exterior or wet conditions.

Regular cleaning with pH-balanced agents, periodic sealing where appropriate, and planned resurfacing intervals extend marble floors and walls for decades, spreading embodied energy and cost over long operational horizons. Future Stone Group provides guidance on cleaning regimes, compatible sealers, and refinishing strategies tailored to specific stones and finishes supplied. Integrating maintenance planning into early specification stages helps clients model long-term operating expenses and demonstrate that well-chosen natural and engineered stone represent financially and environmentally responsible choices.

Market-Specific Approaches: Developed and Emerging Economies

Future Stone Group operates at the intersection of premium developed markets and high-volume emerging economies, requiring different sustainability approaches for each context. High-end residential projects in the USA, Australia, Canada, and Europe demand materials backed by internationally recognized certifications satisfying rigorous green building requirements. Emerging markets and Belt and Road Initiative countries access responsibly sourced stone at value-oriented price points making sustainable choices economically viable for large-scale infrastructure development.

This dual focus reflects market reality: specifications effective for American luxury hotels often require adaptation—not simple replication—when deployed in Central Asian rail stations or Gulf-region affordable housing schemes. The company's established presence serving these diverse geographies enables tailored recommendations on stone packages and finish strategies aligning with local budgets, codes, and construction practices.

Looking Forward: Stone as Strategic Asset

In large-scale projects, marble and engineered stone function as strategic building systems rather than decorative afterthoughts. When specified intelligently—grounded in technical data, lifecycle economics, and proven installation practice—stone surfaces offer rare combinations of durability, design prestige, and long-term cost control.

Future Stone Group's integrated capabilities position the company to support project teams across infrastructure, residential, and hospitality developments worldwide. By pairing material selection with disciplined design and execution, architects, designers, contractors, and homeowners achieve environments balancing premium aesthetics with financial and environmental responsibility.

The path forward requires continued industry evolution toward measurable environmental metrics, third-party verification, and transparent supply chains. For stone to maintain its role in sustainable architecture, producers must demonstrate not just material beauty but documented stewardship of the landscapes and communities from which stone originates.

Visit Future Stone Group's natural stone solutions to explore marble, granite, travertine, onyx, and engineered stone options for sustainable luxury projects. Learn more about cost-effective marble solutions for large-scale developments integrating sustainability with project economics.