The natural stone industry is experiencing a technical renaissance in 2025, driven by advances in quarrying precision, fabrication technologies, and evolving client specifications for sustainable luxury. Interior designers and architects specifying materials for high-end residential and commercial projects face increasingly sophisticated demands: clients expect both dramatic aesthetic impact and verifiable supply chain transparency.

Working directly with quarry-backed suppliers like Future Stone Group—with 13 years of stone production experience and proprietary mine operations—gives design professionals access to consistent material availability and competitive pricing structures that impact project feasibility. This comprehensive analysis examines the technical and aesthetic trends reshaping luxury stone specifications in 2025, with practical guidance for implementation.

Textured Finishes Replace High-Gloss Surfaces

The specification shift from polished to textured stone finishes represents more than aesthetic preference—it addresses practical performance requirements in contemporary interiors. Leathered finishes, achieved through diamond-tipped brush applications, create subtle surface relief that enhances color depth while maintaining the stone's structural integrity. This finish performs exceptionally well in kitchens and bathrooms where fingerprint visibility and water spotting compromise the appearance of polished surfaces.

Honed marble, ground to achieve a matte satin texture without reflective properties, requires periodic sealing due to increased porosity but offers superior scratch concealment in high-traffic applications. The non-reflective surface allows architectural lighting and adjacent design elements to function as intended without competing glare. For commercial hospitality projects, honed travertine flooring delivers the warm, organic aesthetic clients expect while meeting slip-resistance requirements that polished stone cannot satisfy.

Technical considerations for textured finishes include sealing protocols—leathered and honed surfaces typically require initial sealing within 48 hours of installation, followed by annual resealing depending on traffic exposure. Design professionals should specify appropriate sealers matched to stone composition and anticipated use patterns, factoring these maintenance requirements into project budgets and client education protocols.

Large Format Slabs and Book-Matched Installations

Advances in quarrying technology and CNC fabrication equipment now enable consistent production of slabs exceeding 3000mm x 1400mm, fundamentally changing how designers approach continuous surface applications. These oversized formats eliminate seams across kitchen islands, bathroom feature walls, and commercial reception desks, creating uninterrupted visual flow that showcases natural veining patterns.

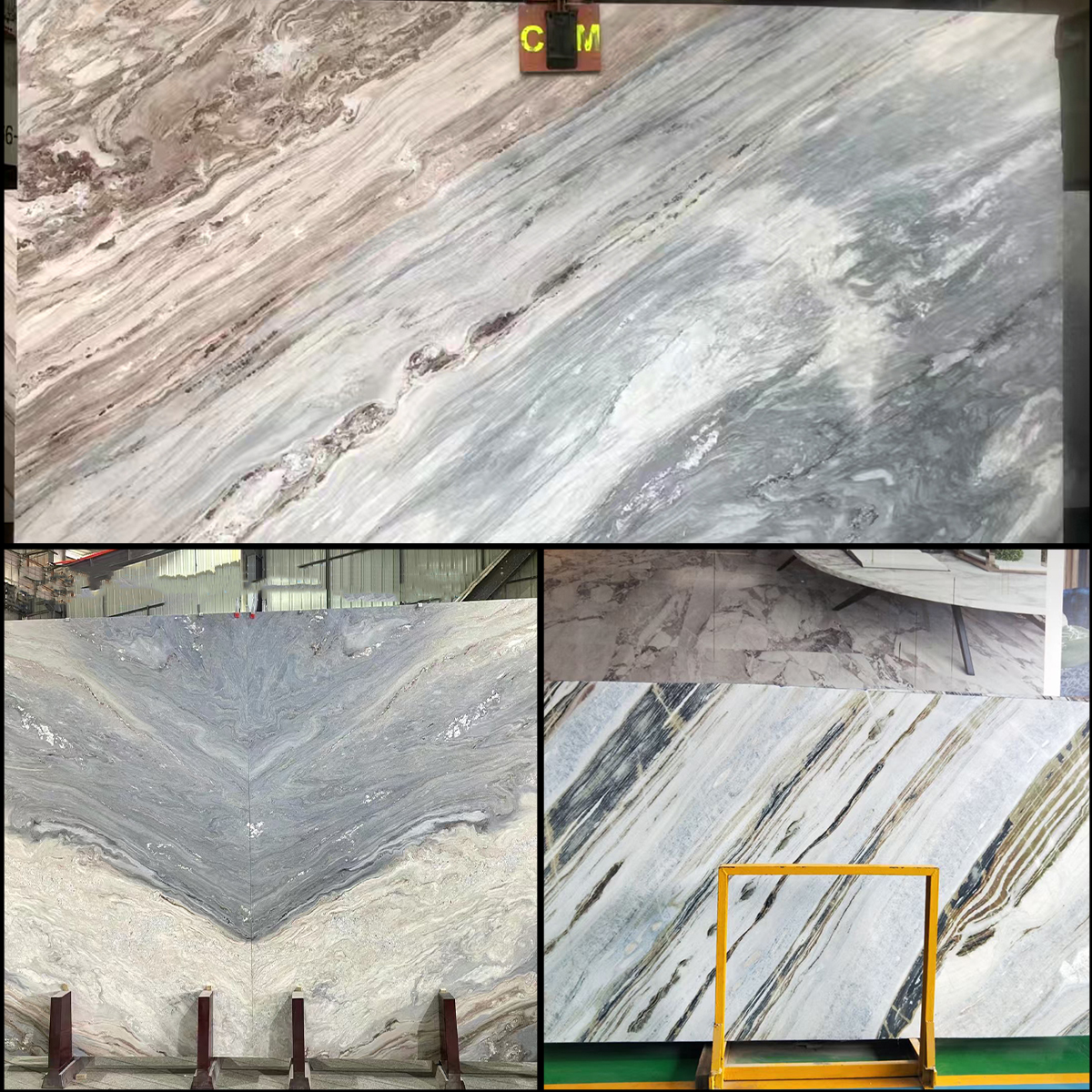

Book-matching—the precise mirroring of consecutive slabs cut from the same block—requires expert fabrication and field coordination but delivers transformative results. When two adjacent slabs are opened like book pages and installed with mirrored veining, the symmetrical pattern creates architectural focal points that justify premium material costs. This technique works optimally with bold-veined marbles like Calacatta and Arabescato where dramatic pattern repetition amplifies visual impact.

The installation process for book-matched walls demands meticulous planning. Fabricators must number slabs during cutting to maintain sequence, accounting for any variation in thickness that affects alignment. On-site, installers use laser leveling systems to ensure perfect vertical and horizontal alignment, as even millimeter-level discrepancies disrupt the mirrored effect. For projects specifying book-matched installations, designers should budget for 15-20% material overage and factor extended lead times for slab selection and fabrication coordination.

| Finish Type | Surface Characteristics | Maintenance Requirements | Optimal Applications | Slip Resistance |

|---|---|---|---|---|

| Leathered | Textured with subtle sheen | Annual sealing; conceals smudges | Kitchen islands, bathroom vanities | Moderate-High |

| Honed | Matte satin, non-reflective | Bi-annual sealing; shows etching | Living areas, commercial lobbies | High |

| Polished | High-gloss, light-reflective | Minimal sealing; shows scratches | Low-traffic walls, decorative panels | Low |

| Hammered | Pronounced dimensional relief | Minimal maintenance | Exterior facades, accent walls | Very High |

Warm Earth Tones Dominate Color Specifications

The chromatic shift toward warm earth tones reflects broader interior design movements emphasizing biophilic principles and residential comfort. Beige travertine varieties sourced from Turkish and Iranian quarries offer natural pitting and tonal variation that creates organic visual interest without overwhelming minimalist interiors. These stones pair effectively with natural oak cabinetry, brass hardware, and warm textile palettes dominating 2025 residential specifications.

Cappuccino and brown marble varieties—particularly those featuring golden or cream veining—perform strongly in open-concept living spaces where continuity between kitchen, dining, and living zones requires cohesive material selection. The inherent warmth of these stones reduces the clinical appearance that cool gray palettes can create in large volumes, making spaces feel more inviting while maintaining luxury positioning.

For designers working with Future Stone Group's extensive inventory, material selection benefits from direct quarry relationships that ensure consistent color matching across multiple slabs—critical for large-format installations where tonal variation between slabs creates visible seams. Year-round stock availability eliminates the extended lead times that can delay project schedules when specifying exotic or limited-production stones.

Exotic Marbles with Dramatic Veining

While warm neutrals dominate overall square footage, strategic deployment of high-contrast exotic marbles creates necessary visual anchors in luxury interiors. Calacatta Viola—featuring distinctive purple-gray veining on white backgrounds—has become particularly sought-after for waterfall island installations and bathroom feature walls where bold pattern makes architectural statements. This marble requires careful slab selection, as veining intensity and color saturation vary significantly within the same block.

Black Marquina marble, characterized by deep black backgrounds with sharp white calcite veining, continues performing strongly in contemporary projects pairing dark stone with matte black plumbing fixtures and minimalist cabinetry. The high-contrast graphic quality of Marquina makes it effective for smaller-scale applications—powder room vanities, fireplace hearths, furniture tops—where material cost per square foot is justified by dramatic impact.

Technical considerations for exotic marbles include structural support requirements for large installations. A 30mm Calacatta Viola waterfall island can exceed 400kg; designers must verify that floor systems can accommodate concentrated loads and specify appropriate mounting systems. For wall-mounted applications, epoxy-based installation systems with mechanical anchoring provide necessary support for heavy stone panels while accommodating differential movement between substrates.

Mixed Stone Material Compositions

The layering of different natural stones within single projects creates depth and textural contrast that single-material installations cannot achieve. Successful mixed-stone specifications require careful consideration of tonal relationships, finish compatibility, and maintenance protocol differences between materials.

Effective combinations include honed marble countertops paired with textured travertine backsplashes, where the material transition creates functional zoning while maintaining tonal harmony. In luxury bathrooms, designers are specifying book-matched marble feature walls with limestone flooring—the dramatic veining draws visual focus upward while durable limestone handles water exposure and foot traffic at floor level.

For custom furniture applications, Future Stone Group's manufacturing capabilities enable integration of multiple stone types within single pieces. A dining table featuring a primary marble surface with contrasting stone inlay borders demonstrates material versatility while creating signature pieces that justify premium pricing. These mixed-material furniture specifications require precise CNC cutting and skilled hand-finishing to ensure flush transitions between different stone types.

Sustainable Sourcing and Supply Chain Transparency

Sustainable stone sourcing has transitioned from optional consideration to mandatory specification requirement for many luxury clients and projects pursuing green building certification. Designers now field detailed questions about quarry operations, transportation impacts, and labor practices during material selection processes.

Modern quarrying operations employ precision extraction techniques using diamond wire saws and controlled blasting that minimize overburden removal and reduce ecosystem disruption. Operators focused on sustainability implement biodiversity conservation measures including wildlife corridors and native vegetation buffers, with post-extraction site restoration protocols that return quarried land to productive ecological function.

Future Stone Group's ownership of proprietary mines enables direct oversight of extraction practices and eliminates intermediary supply chain steps that add both cost and environmental impact. For designers specifying materials for LEED-certified projects, documentation of sustainable quarrying practices, transportation distances, and material longevity contributes to Materials and Resources credit achievement. Natural stone's exceptional durability—properly installed marble floors regularly exceed 50-year service lives—positions it favorably in lifecycle assessment comparisons against synthetic alternatives requiring replacement every 10-15 years.

The technical aspect of sustainable stone specification includes consideration of extraction efficiency. Advanced 3D geological modeling and GPS surveying enable quarry operators to map deposit characteristics before extraction, optimizing cut patterns to maximize usable material yield and minimize waste. This precision reduces the ratio of extracted volume to saleable product, improving both economic and environmental performance.

Translucent Stone and Backlit Applications

Translucent stones—primarily onyx varieties and certain quartzites—enable architectural lighting integrations that transform functional surfaces into illuminated focal points. When backlit with LED systems, these stones reveal internal crystalline structures and layered veining patterns invisible under standard lighting conditions.

Successful backlit stone installations require coordination between stone fabrication, electrical design, and installation teams. The stone must be cut to specified thickness (typically 20-30mm for optimal translucency), with backside CNC texturing to diffuse light evenly across the surface. LED panels or strip lighting systems mount to substrate walls or within custom framing, with thermal management considerations to prevent excessive heat buildup behind the stone.

Popular applications for backlit translucent stone include luxury bathroom vanity walls, hotel bar fronts, commercial reception desks, and residential powder room feature walls where dramatic lighting effects create memorable spatial experiences. Onyx varieties with pronounced banding and rich color saturation—including honey onyx, green onyx, and white onyx—deliver particularly striking results when properly illuminated from behind.

Technical specifications for backlit installations must address structural support for stone panels, electrical system integration, and maintenance access for LED components. Designers should specify removable panel systems that allow access to electrical components without demolishing stone installations, factoring in LED lifespan (typically 50,000+ hours) and eventual replacement requirements.

Dark Stones for Contemporary Luxury Contrast

While warm earth tones dominate overall specifications, strategic deployment of dark stones creates necessary visual weight and sophisticated contrast in contemporary luxury interiors. Black granite, dark marble, and deep brown stones ground kitchen islands in light-filled open-concept spaces, define entry sequences in residential lobbies, and add gravitas to luxury bathroom designs.

Dark stone specifications require different technical considerations than light materials. Surface scratches and water marks show more prominently on black stones, making leathered finishes preferable to polished surfaces for high-use applications. Edge treatments—particularly on waterfall installations—demand precise fabrication, as any misalignment or gap shows clearly against dark backgrounds.

For designers working with Future Stone Group's material portfolio, dark stone options include black granite from proprietary quarries, ensuring consistent quality and competitive pricing structures that improve project economics. The company's 13-year stone production experience includes specialized expertise in dark material fabrication, where standard cutting and polishing parameters require adjustment to achieve optimal surface quality.

Custom Marble Flooring and Decorative Inlays

Custom marble flooring designs incorporating water jet-cut patterns and multi-material inlays represent the pinnacle of stone craftsmanship in luxury interiors. Future Stone Group's design team specializes in developing individualized marble flooring patterns that transform functional surfaces into artistic compositions.

Water jet cutting technology enables precision pattern execution with tolerances under 0.5mm, allowing complex geometric designs, organic curves, and detailed representational imagery in stone. These custom installations typically combine multiple stone varieties—contrasting colors, textures, and finishes—to create visual depth and definition within pattern elements.

Technical execution of custom stone flooring requires detailed CAD drawings translated to CNC and water jet cutting equipment, with numbered piece identification for field assembly. Installation follows specific sequence protocols to maintain pattern integrity, with epoxy-based adhesive systems providing both structural bond and gap-filling capacity for tight joints. For high-traffic commercial applications, designers should specify hardness-matched stones to ensure even wear patterns across multi-material compositions.

Frequently Asked Questions

What thickness should I specify for large-format stone slabs in waterfall island installations?

Waterfall islands typically require 30mm stone thickness for structural integrity and visual proportion, though 20mm material can work for smaller islands with proper support structures. Edge profiles and mitered corner joints affect thickness requirements—book-matched waterfall installations benefit from 30mm material that provides adequate thickness for invisible seam execution.

How do leathered and honed finishes differ in maintenance requirements?

Both finishes require more frequent sealing than polished marble—typically annually for leathered surfaces and bi-annually for honed. Leathered finishes better conceal fingerprints, water spots, and minor scratches due to textured surfaces, while honed marble shows etching from acidic substances more prominently than leathered alternatives. Specify penetrating sealers rated for textured surfaces rather than topical coatings.

What are the practical challenges of book-matched marble installations?

Book-matching requires consecutive slabs from the same block, precise fabrication to maintain veining alignment, and expert installation with laser leveling systems. Budget 15-20% material overage for potential breakage and pattern matching adjustments, and expect 4-6 week lead times beyond standard slab procurement for selection and fabrication coordination. Slab thickness variation can disrupt mirrored symmetry if not addressed during fabrication.

Which stone types work best for backlit translucent installations?

Onyx varieties deliver optimal translucency and dramatic color saturation when backlit, with honey onyx, white onyx, and green onyx performing particularly well. Certain quartzites also work effectively for backlit applications. Stone should be cut to 20-30mm thickness for proper light transmission, with backside CNC texturing to ensure even illumination without hotspots.

How does direct quarry sourcing affect material costs and lead times?

Direct quarry relationships eliminate intermediary markups and improve material consistency, particularly for large projects requiring multiple container loads from the same block. Lead times can be shorter for in-stock materials from owned quarries, though custom selections may require quarry visits and extraction scheduling. Year-round inventory availability at Future Stone Group minimizes project delays common with specialty stone procurement.

What documentation is required for sustainable stone specifications in LEED projects?

LEED Materials and Resources credits require documentation of extraction location, transportation distance, recycled content (if applicable), and rapidly renewable content. Some projects also request quarry certification for environmental management practices, worker safety protocols, and site restoration plans. Suppliers with owned quarries can provide comprehensive chain-of-custody documentation from extraction through delivery.

Are warm-toned travertines suitable for high-moisture bathroom applications?

Travertine performs well in bathrooms when properly sealed and maintained, though inherent porosity requires more frequent sealing than marble or granite. Specify filled travertine for smoother surfaces with reduced absorption, and plan for initial sealing before grouting followed by annual resealing. Honed or tumbled finishes work better than polished for slip resistance in wet areas. Adequate substrate waterproofing is essential regardless of stone selection.

Implementation Guidance for Design Professionals

Successful execution of 2025 stone trends requires coordination across design development, material procurement, fabrication, and installation phases. Early supplier engagement—ideally during schematic design—enables slab selection that aligns with design intent while accommodating material characteristics like veining direction, color variation, and inherent structural properties.

For projects specifying exotic marbles or book-matched installations, in-person quarry or slab yard visits allow designers to review actual materials rather than relying on samples that may not represent production reality. Future Stone Group's showroom facilities display extensive natural stone selections with year-round inventory access, enabling immediate project matching without extended procurement delays.

Budget considerations for 2025 stone trends should account for increased fabrication complexity. Large-format slabs require specialized handling equipment and transportation; book-matched installations need extended fabrication time for precise matching; custom water jet inlays involve design development and cutting coordination. Working with experienced stone suppliers offering one-stop project solutions—from design consultation through installation support—streamlines coordination and reduces the risk of costly field corrections.

The technical expertise required for contemporary stone installations increasingly favors suppliers with vertical integration across quarrying, fabrication, and project support. Future Stone Group's 13-year production experience, proprietary mine operations, and commitment to 24-hour technical service provides design professionals with the resources necessary to execute complex specifications successfully. Access to installation guidance, logistics tracking, and responsive problem-solving during construction phases differentiates suppliers capable of supporting luxury project standards from commodity material distributors.

Natural stone design in 2025 represents a sophisticated evolution beyond simple material selection toward holistic consideration of aesthetics, performance, sustainability, and supply chain transparency. For interior designers and architects committed to delivering exceptional luxury interiors, partnership with quarry-backed suppliers offering technical expertise and comprehensive project support proves essential to successful execution.

Request material samples and schedule a design consultation at https://www.futurestonegroup.com/