Selecting the right surface material for your luxury renovation or new construction project requires understanding both traditional and engineered options. Artificial marble has emerged as a sophisticated alternative to natural stone, combining the timeless elegance of marble with enhanced durability and practical advantages. This engineered material offers design professionals and discerning homeowners a versatile solution that addresses many limitations of quarried stone while maintaining aesthetic appeal.

Whether you're an architect specifying materials for a high-end residential project, an interior designer curating a cohesive aesthetic, or a property developer evaluating cost-effective luxury finishes, understanding artificial marble's composition, manufacturing process, and performance characteristics enables informed decision-making. This comprehensive guide explores everything from the molecular composition of engineering marble to real-world applications in kitchens, bathrooms, and commercial spaces. You'll discover how modern manufacturing techniques create consistent, customizable surfaces that rival natural marble's beauty while offering superior stain resistance, lower maintenance requirements, and predictable pricing.

By comparing artificial marble directly with natural stone across critical factors like durability, cost, and maintenance, this guide provides the practical framework needed to determine which material best suits your specific project requirements and budget constraints.

Understanding Artificial Marble: Definition and Composition

Artificial marble is a composite material engineered to replicate the aesthetic qualities of natural marble while incorporating enhanced performance characteristics. This manufactured stone combines crushed natural marble aggregate with advanced polymer resins, creating a surface that mimics marble's distinctive veining and translucent depth. The material emerged in the 1960s as manufacturers sought to address natural marble's porosity and maintenance challenges while making marble-like surfaces more accessible.

The typical composition consists of 75-80% crushed marble chips or marble dust sourced from quarries, combined with 10-15% polymer resins—either polyester or acrylic-based binding agents. The remaining 5-10% comprises pigments for color matching, additives for UV stability, and catalysts that facilitate the curing process. This precise formulation creates a non-porous surface with consistent coloration throughout the material's thickness.

Manufacturing control allows artificial marble to eliminate the natural variations, fissures, and color inconsistencies inherent in quarried stone. The resin binder fills microscopic gaps between marble particles, creating an impermeable surface that resists moisture absorption and staining. This engineered approach produces slabs with predictable performance characteristics and uniform appearance, making material selection and installation planning more straightforward for large-scale projects.

The industry uses several interchangeable terms for this material category. Engineering marble typically refers to products with higher natural stone content and minimal resin, while "cultured marble" describes polyester-based formulations popular in bathroom applications. "Synthetic marble" and "composite marble" serve as umbrella terms encompassing all resin-bound marble products. Understanding these distinctions helps when reviewing product specifications and comparing offerings from different artificial marble manufacturers.

Types of Artificial Marble and Engineered Stone

The artificial marble category encompasses several distinct product types, each formulated for specific applications and performance requirements. Understanding these variations enables material selection aligned with project demands, aesthetic goals, and budget parameters.

Quartz Artificial Marble

Quartz artificial marble represents the premium tier of engineered stone products, containing 93-95% natural quartz crystals bound with 5-7% polymer resins. This composition delivers exceptional hardness rating—typically 7 on Mohs scale—making it the most scratch-resistant option for high-traffic surfaces. The high quartz content provides superior strength and impact resistance compared to marble-based composites.

Manufacturers process quartz through specialized vibrocompression techniques that compact the material under intense pressure, eliminating air pockets and creating a dense, non-porous surface. This production method results in consistent thickness and minimal internal stress, reducing the risk of cracking during fabrication or installation. Quartz surfaces excel in commercial kitchens, restaurant countertops, and luxury residential applications where durability justifies premium pricing. The material's resistance to acids and alkalis makes it suitable for laboratory surfaces and food preparation areas requiring stringent hygiene standards.

Cultured Marble

Cultured marble utilizes 75-80% natural marble dust combined with polyester resin in a casting process that enables complex shapes and integrated features. This formulation allows manufacturers to create seamless vanity tops with integrated sinks, eliminating the grout lines where moisture and bacteria accumulate. The gel-coat surface layer provides initial stain resistance, though this protective coating may wear over time in high-use areas.

The casting process accommodates custom color matching and pattern creation, making cultured marble popular for bathroom renovations where matching existing décor proves essential. Material costs typically run 30-40% lower than solid surface alternatives, positioning cultured marble as an economical choice for residential bathroom projects. However, the polyester resin composition offers less heat resistance than acrylic-based alternatives, requiring careful consideration for applications near heat-generating fixtures.

Engineering Marble Variations

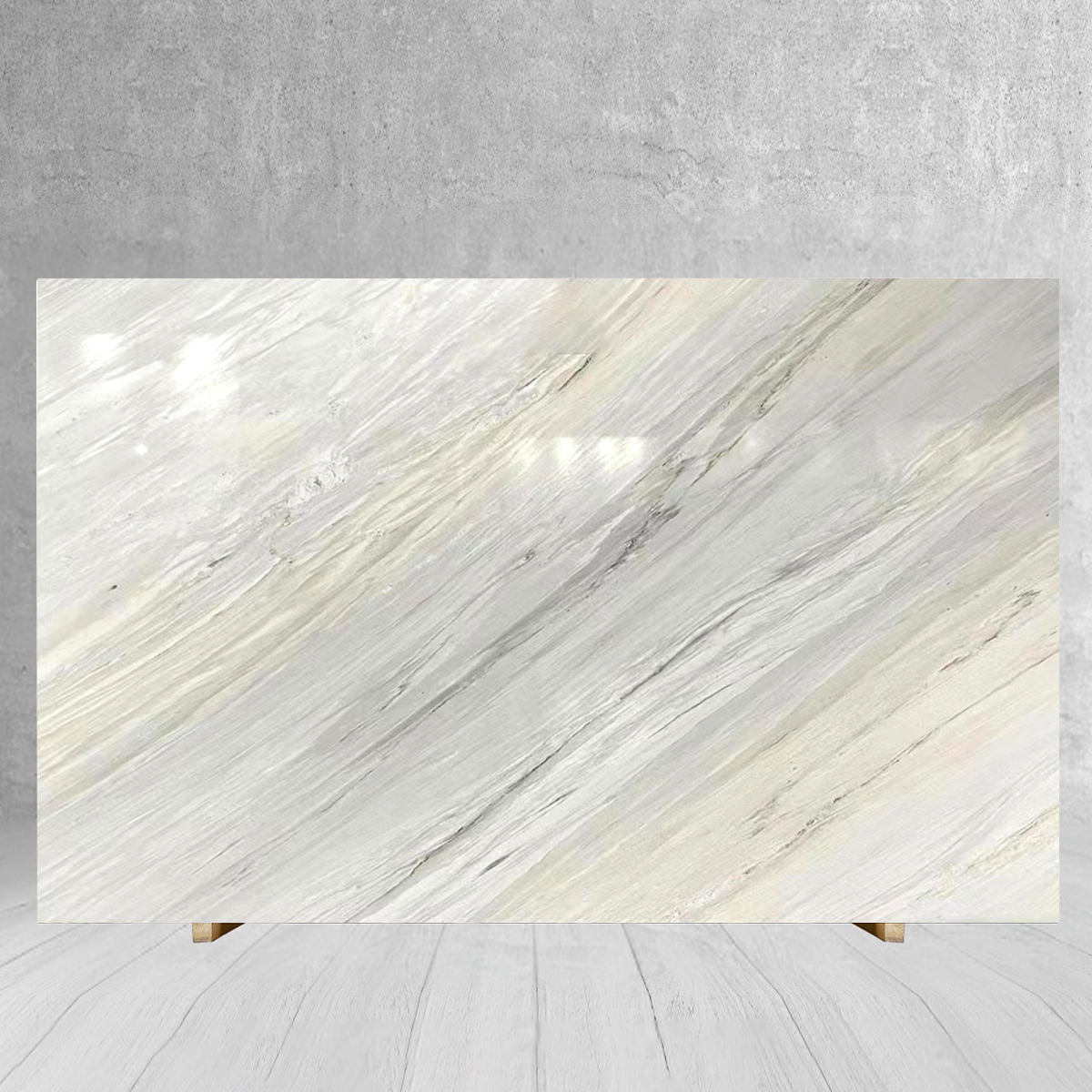

Engineering marble formulations emphasize natural stone content, using recycled marble fragments from quarrying operations bonded with minimal resin content—sometimes as low as 8-10% by weight. This composition preserves more of natural marble's aesthetic character, including subtle color variations and authentic veining patterns. The higher stone ratio creates surfaces with appearance nearly indistinguishable from natural marble at considerably lower cost.

Some manufacturers produce terrazzo-style engineered marble by incorporating marble chips ranging from 10-20mm in size, creating distinctive aggregate patterns visible on the polished surface. These products appeal to design professionals seeking the artisanal character of traditional terrazzo with the installation advantages and consistent pricing of engineered materials. Light brown artificial marble and light beige variations demonstrate how pigment selection creates earth-tone palettes suitable for contemporary and traditional design schemes.

The composition ratio directly influences performance characteristics. Higher stone content increases brittleness and requires more careful handling during fabrication, while increased resin content enhances flexibility and impact resistance at the expense of natural appearance. Specifying the appropriate type requires balancing aesthetic priorities against functional demands and budget constraints.

How Artificial Marble Stone Is Manufactured

The production of artificial marble stone involves precision manufacturing processes that control material properties and ensure consistent quality across production runs. Understanding these manufacturing stages provides insight into the material's performance characteristics and helps explain price variations between products.

Material Preparation and Selection

Manufacturing begins with selecting and grading natural marble aggregates. Quarry operators separate marble based on color, purity, and mineral content, then crush the stone through industrial grinders producing particle sizes ranging from fine dust (under 0.1mm) to larger chips (up to 10mm). Manufacturers blend different particle sizes to optimize packing density and minimize resin requirements while maintaining strength.

The crushing process generates marble dust as a byproduct of dimensional stone fabrication, creating a sustainable use for material otherwise discarded as quarry waste. This recycling aspect reduces the environmental impact compared to quarrying whole marble blocks. Resin selection depends on the intended application—polyester resins offer cost advantages for lower-end products, while acrylic resins provide superior UV stability and reduced yellowing for premium applications and outdoor installations.

Mixing and Pigmentation

Industrial mixers combine marble aggregate with liquid resin, pigments, and additives under controlled temperature conditions. The mixing duration and speed critically affect the final product—insufficient mixing leaves resin-poor areas prone to weakness, while excessive mixing introduces air bubbles that compromise surface quality. Manufacturers add pigments during this stage, adjusting color intensity to match natural marble varieties or create custom hues for specific projects.

Advanced production facilities utilize computer-controlled dispensing systems that precisely measure component ratios, ensuring batch-to-batch consistency essential for large installations requiring multiple slabs. Some manufacturers inject contrasting pigments during the mixing stage, creating veining patterns that mimic natural marble's geological formations. This artistic process requires skilled technicians who understand how pigments flow and settle within the resin matrix.

Molding Under Vacuum and Pressure

The mixed material flows into steel or silicone molds sized to produce standard slab dimensions, typically 3000mm x 1400mm for countertop applications. Vacuum processing removes entrapped air that would create voids and structural weaknesses in the cured material. Manufacturers then apply hydraulic pressure—ranging from 60 to 100 tons depending on slab thickness—compacting the mixture and forcing resin to completely saturate the marble particles.

This compression phase proves critical for achieving the non-porous surface that distinguishes quality artificial marble from inferior products. Inadequate pressure leaves microscopic channels where liquids can penetrate, compromising stain resistance. The mold configuration determines surface texture—polished steel molds create glossy finishes, while textured molds produce honed or leathered surface effects.

Curing and Finishing

Molds move into controlled-temperature ovens where heat curing occurs at 60-80°C for 4-8 hours, depending on slab thickness and resin formulation. The heating process initiates polymerization, transforming liquid resin into solid polymer that permanently bonds marble particles. Temperature control prevents thermal stress that could cause cracking or warping during cooldown.

After cooling to ambient temperature, technicians demold slabs and inspect for surface defects, color consistency, and structural integrity. CNC-controlled saws cut slabs to specified dimensions with tolerances under 0.5mm, essential for seamless installations. Final polishing employs progressively finer abrasive pads—typically progressing from 50-grit through 3000-grit—producing the mirror-like finish associated with premium marble surfaces. Some manufacturers apply additional sealants or protective coatings, though properly manufactured artificial marble's non-porous nature requires no sealing for moisture resistance.

Quality manufacturers maintain detailed production records tracking raw material sources, mixing ratios, curing parameters, and quality control measurements, enabling traceability and consistency across production runs. This manufacturing transparency builds confidence with architects and contractors specifying materials for high-value projects.

Artificial Marble vs Natural Marble: Key Differences

Selecting between artificial and natural marble requires evaluating multiple factors that impact both initial investment and long-term ownership costs. This detailed comparison examines the critical differences affecting material performance, maintenance requirements, and aesthetic outcomes.

Cost and Budget Implications

Artificial marble delivers significant cost advantages, typically priced between $15-65 per square foot installed, compared to natural marble's $40-100+ per square foot range. This 20-40% cost differential stems from predictable manufacturing costs, reduced material waste during fabrication, and lower transportation expenses due to artificial marble's lighter weight. Natural marble pricing varies dramatically based on rarity, origin, and quality grade—exotic varieties like Calacatta or Statuario command premium prices due to limited quarry availability.

Beyond initial material costs, installation expenses differ considerably. Natural marble's weight requires additional structural support and specialized handling equipment, increasing labor costs by 15-25% compared to artificial alternatives. The brittleness of natural marble generates more waste during cutting and fabrication—experienced fabricators expect 15-20% waste factors when templating natural marble, while artificial marble's consistent composition reduces waste to 8-12%.

For large commercial projects or multi-unit residential developments, engineering marble provides budget predictability absent from natural stone procurement. Quarry supply fluctuations and quality variations in natural marble can delay projects or require design modifications, while manufactured materials offer guaranteed availability and consistent pricing throughout project duration.

Durability and Performance

The non-porous surface of artificial marble fundamentally changes maintenance dynamics. Natural marble's porous structure absorbs liquids, requiring immediate cleanup of spills—particularly acidic substances like wine, citrus juice, or vinegar that etch marble's calcium carbonate composition. Artificial marble's resin binder creates an impermeable barrier resisting stain absorption and acid etching, though concentrated acids can still damage the resin over extended contact periods.

Scratch resistance varies by product type. Quartz artificial marble ranks among the most scratch-resistant countertop materials, while marble-based cultured products offer moderate scratch resistance—superior to natural marble but less robust than quartz. Natural marble's relatively soft composition (3-4 on Mohs hardness scale) scratches easily from normal kitchen use, developing patina over time that some owners appreciate as character while others perceive as wear.

Impact resistance favors artificial marble, which flexes slightly under stress due to polymer content, absorbing impacts that would crack natural stone. Natural marble's crystalline structure fractures when subjected to sudden impacts, particularly near unsupported edges. However, repairing damage presents challenges—chips in natural marble can be filled and polished to near-invisible repairs, while damaged artificial marble's resin content makes seamless repairs difficult, often requiring section replacement.

Maintenance Requirements

Natural marble demands ongoing maintenance protocols that artificial alternatives eliminate. Marble requires resealing every 6-12 months to maintain stain resistance, with sealer costs and professional application adding $200-400 annually for typical residential countertops. Daily cleaning necessitates pH-neutral cleaners specifically formulated for natural stone—common household cleaners containing acids or alkalis damage marble's surface.

Artificial marble stone requires only routine cleaning with mild soap and water. The non-porous surface prevents bacterial growth and mildew formation, important considerations for bathroom applications and commercial food preparation areas. However, artificial marble's resin content limits heat resistance—placing hot cookware directly on surfaces can cause discoloration or softening, requiring use of trivets and hot pads. Natural marble withstands high temperatures without damage, tolerating direct contact with heated cookware up to 300°C.

Aesthetic Considerations and Design Flexibility

Natural marble's geological formation creates genuinely unique patterns in each slab—no two pieces exhibit identical veining or color variation. This uniqueness appeals to design professionals and homeowners valuing one-of-a-kind materials. The depth and translucency of natural marble, particularly in backlit applications, creates visual effects difficult to replicate in engineered products.

Artificial marble offers design consistency, with slabs from the same production run exhibiting identical patterns and coloring. This uniformity simplifies large installations requiring multiple slabs with seamless pattern matching—critical for commercial lobbies, hotel bathrooms, or open-concept kitchen designs. Manufacturers can produce custom colors unavailable in natural stone, including contemporary white and gray palettes or warm light brown and beige tones that complement specific design schemes.

The decision ultimately balances aesthetic authenticity against practical performance. Projects prioritizing maintenance-free longevity and budget predictability favor artificial marble, while installations where natural material authenticity and unique character justify premium costs and ongoing maintenance lean toward natural stone. Many high-end projects strategically combine both materials—natural marble in showcase areas like entry lobbies and artificial alternatives in functional spaces like kitchen countertops.

Benefits and Advantages of Artificial Marble

Artificial marble's engineered composition delivers specific advantages that address common challenges associated with natural stone surfaces. Understanding these benefits helps determine whether artificial alternatives suit particular project requirements and operational contexts.

Superior Moisture and Stain Resistance

The non-porous surface characteristic represents artificial marble's most significant functional advantage. The resin binder completely encapsulates marble particles, creating an impermeable barrier that prevents liquid absorption. This quality proves essential in moisture-prone environments—bathroom vanities, shower walls, and commercial restroom applications benefit from surfaces that resist water penetration and prevent mildew growth behind or within the material.

Stain resistance extends to oils, wine, coffee, and cosmetics that permanently discolor natural marble. The sealed surface allows simple cleanup of spills without urgency, eliminating the immediate-response requirement that natural marble demands. Food preparation areas particularly benefit, as acidic ingredients like tomatoes, lemons, or vinegar that etch natural marble's surface leave artificial marble unaffected during typical kitchen use.

Consistent Appearance and Pattern Matching

Manufacturing control ensures slabs from the same production batch exhibit identical coloring, veining patterns, and surface characteristics. This consistency eliminates the pattern-matching challenges that complicate natural marble installations, particularly in large projects requiring multiple slabs. Designers can specify exact appearance knowing delivered materials will match approved samples, reducing on-site installation complications and client disputes over material appearance.

The consistent composition throughout the material's thickness means edges, cutouts, and fabricated details match the surface appearance—natural marble often reveals color variations or pattern discontinuities when viewed from edges or reveals. This through-body consistency proves valuable for waterfall edge countertops, integrated backsplashes, and furniture pieces where multiple surfaces and angles remain visible.

Reduced Maintenance and Lifecycle Costs

Eliminating sealing requirements and specialized cleaning products reduces ongoing maintenance costs and simplifies care protocols. Commercial properties benefit particularly from reduced maintenance labor—hospitality properties with hundreds of bathroom vanities or commercial buildings with extensive lobby flooring realize substantial savings over 10-15 year service life compared to natural marble maintenance costs.

The material's lighter weight—typically 30-40% less than equivalent natural marble—reduces transportation costs and simplifies handling during installation. This weight advantage enables thinner profile applications where structural loading limits use of traditional stone, expanding design possibilities in renovation projects with existing structure limitations.

Customization and Color Options

Manufacturers can formulate artificial marble in virtually unlimited colors, including trendy gray palettes, pure whites, and earth tones like beige and brown variations impossible to source consistently in natural stone. This color flexibility allows designers to specify exact hues matching broader color schemes or corporate branding requirements. Custom color production typically requires minimum order quantities, but projects requiring 50+ square meters often justify custom formulation costs.

The molding process accommodates integrated features like seamless sinks, drain boards, and backsplash coves that eliminate grout joints where moisture and bacteria accumulate. These monolithic installations create clean-lined contemporary aesthetics while simplifying cleaning and maintenance. Furniture applications benefit from molding capabilities that create complex curved forms and edge details difficult or impossible to achieve with natural stone fabrication.

Environmental Considerations

Artificial marble production utilizes marble dust and chips generated as waste products from natural stone quarrying and fabrication operations. This recycling aspect reduces quarry waste disposal while decreasing demand for pristine marble blocks. Manufacturing facilities operate year-round independent of weather conditions that affect quarry operations, providing stable supply chains less vulnerable to seasonal disruptions.

However, the polymer resin component—typically derived from petroleum—raises environmental considerations that natural stone avoids. Some manufacturers now offer bio-based resin alternatives sourced from renewable feedstocks, though these formulations typically command price premiums. Life cycle assessments show mixed environmental outcomes depending on transportation distances, installation waste rates, and operational energy consumption over service life.

Best Applications for Artificial Marble

Matching material properties to application requirements ensures optimal performance and customer satisfaction. Artificial marble excels in specific contexts where its engineered characteristics address functional demands or design constraints.

Kitchen Countertops and Food Preparation Surfaces

Artificial marble for kitchen applications capitalizes on stain resistance and ease of maintenance critical in food preparation environments. The non-porous surface prevents absorption of cooking oils, wine, and food-based stains that permanently discolor natural marble. Daily cleaning requires only soap and water, eliminating the specialized pH-neutral cleaner requirements and periodic resealing that natural marble demands.

The consistent surface hardness resists scratching from normal kitchen use, though cutting boards remain recommended to preserve appearance and protect knife edges. Edge profiles and cutouts for sinks and cooktops can be fabricated with precision tolerances under 0.5mm, ensuring proper fit and professional installation appearance. However, heat resistance limitations require using trivets under hot cookware—prolonged contact with heated pots and pans above 150°C can cause discoloration or surface softening.

Backsplash applications benefit from artificial marble's moisture resistance, particularly behind sinks where water splashing occurs frequently. The material's moldability allows creating integrated backsplashes that eliminate the grout joint between countertop and wall surface, providing seamless appearance and simplified cleaning. Color customization enables matching countertops to cabinet finishes or creating contrasting accent walls that enhance kitchen design schemes.

Bathroom Vanities and Shower Surrounds

Moisture-rich bathroom environments represent ideal applications for artificial marble's non-porous composition. Vanity tops with integrated sinks eliminate the joint between bowl and countertop where water accumulates and mildew develops. The seamless construction simplifies cleaning while creating contemporary aesthetics popular in luxury residential and hospitality projects.

Shower wall panels fabricated from large-format artificial marble slabs minimize grout joints that require ongoing maintenance and eventually fail, allowing water penetration behind tile installations. The material withstands constant humidity exposure without degradation, maintaining appearance and structural integrity throughout 15-25 year service life. Manufacturers offer textures that provide slip resistance for shower floors while maintaining the elegant appearance of polished marble.

Custom color capabilities enable matching existing bathroom fixtures and tile selections, important in renovation projects where complete material replacement proves cost-prohibitive. Light beige and neutral tones create spa-like aesthetics while concealing minor water spotting and soap residue between cleanings.

Commercial and High-Traffic Applications

Hospitality properties, corporate offices, and retail environments require surfaces balancing aesthetic sophistication with durability and maintenance efficiency. Artificial marble's scratch and stain resistance withstands heavy use without developing the worn appearance that natural marble exhibits in high-traffic locations. The consistent appearance across multiple slabs enables large installations maintaining visual continuity throughout expansive lobbies or corridors.

Lower maintenance requirements reduce operational costs for property managers overseeing multiple locations—eliminating professional resealing services and specialized cleaning products simplifies maintenance protocols and reduces labor hours. The material's impact resistance reduces replacement costs from accidental damage, important consideration in public spaces where collisions with luggage, equipment carts, or furniture occur regularly.

Reception desks, bar tops, and retail displays benefit from custom color options that reinforce brand identity and coordinate with broader interior design schemes. The material's formability allows creating curved surfaces and integrated features like cable management channels impossible to achieve with natural stone fabrication.

Furniture and Decorative Applications

Dining tables, coffee tables, and console furniture featuring marble surfaces gain practical advantages from artificial marble's stain resistance and consistent appearance. The material withstands wine spills, condensation rings, and food contact that damage natural marble furniture requiring coasters and protective pads. Furniture manufacturers appreciate the material's lighter weight, which reduces shipping costs and simplifies installation of large pieces.

The through-body composition means table edges and pedestals can be fabricated showing matching patterns without the color variation and structural weakness often visible in natural marble furniture components. Custom colors enable creating furniture pieces coordinating with specific interior palettes or limited-edition collections. The material's moldability accommodates integrated features like drawer fronts or carved details that enhance design sophistication.

Architectural details like fireplace surrounds, wall cladding, and column covers utilize artificial marble's consistent appearance and lighter weight compared to natural stone alternatives. The reduced structural loading enables applications where building codes or existing construction limit natural stone installation. Projects can explore our natural stone options alongside artificial alternatives to determine optimal solutions for specific design requirements.

Durability, Lifespan and Maintenance Guide

Understanding proper care protocols and realistic longevity expectations ensures artificial marble surfaces maintain appearance and performance throughout their service life.

Expected Service Life

Quality artificial marble stone installations last 15-25 years under normal residential use, with commercial applications in moderate-traffic environments achieving similar longevity. Service life depends on multiple factors including material quality, installation craftsmanship, maintenance practices, and use intensity. Premium products with high marble content and acrylic resins typically outlast economy-grade cultured marble using polyester resin formulations.

The gel coat or surface layer represents the primary wear zone—once worn through to underlying composite material, the surface becomes more vulnerable to staining and requires replacement. Countertops in moderate-use kitchens typically maintain appearance for 15-20 years before showing significant wear, while bathroom vanities in powder rooms may exceed 25 years due to lighter use. High-traffic commercial installations may require refinishing or replacement within 10-15 years as surface wear accumulates.

Comparing longevity to alternatives provides context—laminate countertops typically last 10-15 years, solid surface materials 15-20 years, granite 20-30 years, and natural marble 25-50+ years with proper maintenance. The cost-per-year calculation often favors artificial marble despite shorter absolute lifespan compared to natural stone, particularly when factoring maintenance cost savings.

Daily Cleaning and Routine Care

Maintaining artificial marble requires minimal effort and no specialized products. Daily cleaning involves wiping surfaces with warm water and mild dish soap using soft cloths or non-abrasive sponges. This simple protocol removes oils, food residue, and everyday grime without damaging the surface. Avoid abrasive cleaners, scouring pads, or steel wool that scratch the polished finish—even minor scratches accumulate over time, dulling appearance and creating texture where dirt accumulates.

For stubborn stains or dried food, create a paste from baking soda and water, apply to the affected area, and gently rub with soft cloth. Allow the paste to sit for 5-10 minutes before rinsing thoroughly. This gentle abrasive action removes most stains without chemical cleaners. Avoid acidic cleaners including vinegar, lemon juice, or commercial bathroom cleaners containing acids that can damage the resin binder over time.

Weekly cleaning should include disinfection using diluted bleach solution (1:10 ratio bleach to water) or commercial disinfectants labeled safe for solid surfaces. Apply the solution, allow 5-minute contact time, then rinse thoroughly and dry. This protocol proves especially important for kitchen countertops and bathroom vanities where bacterial contamination concerns exist.

Heat Protection and Damage Prevention

The polymer resin content limits heat resistance compared to natural stone surfaces. Always use trivets, hot pads, or silicone mats under hot cookware, including pots directly from stovetop burners and dishes removed from ovens. Prolonged contact with heat sources above 150°C can cause several damage types: discoloration creating permanent white or yellowed spots, surface softening that leaves impressions from the hot object, and in extreme cases, cracking or blistering where resin degrades.

Hair styling tools including curling irons and flat irons cause similar thermal damage when placed directly on bathroom vanities. Install heat-resistant mats near electrical outlets where styling tools are typically used, or mount heat-resistant holsters to walls for secure storage during cooling. Small appliances like coffee makers, toasters, and electric kettles should rest on protective mats to prevent cumulative heat exposure that gradually damages surfaces.

Scratch Prevention and Surface Protection

Despite superior scratch resistance compared to natural marble, artificial marble surfaces still benefit from protective practices. Use cutting boards for all food preparation—knife cuts accumulate over time, creating visible scratches and texture changes. Avoid dragging heavy or abrasive objects across surfaces, including small appliances, ceramic cookware with rough bases, or decorative items with unfinished bottoms.

Apply felt pads to bottoms of frequently used items like soap dispensers, utensil holders, and decorative objects that might shift during use. This simple precaution prevents abrasion from repeated small movements. In commercial applications, specify edge guards or protective barriers in areas where equipment carts, luggage, or heavy objects might impact counters or wall cladding.

Repair Considerations and Limitations

Surface damage to artificial marble proves more challenging to repair than natural stone due to the resin component. Small scratches can sometimes be buffed out using fine polishing compounds and buffing pads, though this approach works only for very shallow surface scratches that haven't penetrated through the gel coat layer. Deeper scratches, chips, or cracks typically require professional repair or section replacement.

Professional repair technicians can sometimes fill chips with color-matched resin compounds, sand smooth, and polish to blend repairs. However, these repairs rarely achieve invisible results—color matching proves difficult, and repaired areas often show slight texture or sheen differences. Extensive damage may necessitate replacing entire sections, which can prove difficult if the original color has been discontinued or if surrounding material has aged creating visible color difference with new replacement material.

This repair limitation underscores the importance of preventive maintenance and careful use. While artificial marble resists most damage better than natural stone, the inability to refinish or repair damaged areas as effectively as natural marble can represents a significant consideration for long-term value assessment.

Choosing the Right Artificial Marble for Your Project

Selecting appropriate artificial marble requires evaluating multiple factors including application requirements, design goals, budget parameters, and supplier capabilities. This systematic approach ensures material selection aligned with project success criteria.

Application-Specific Requirements

Begin by analyzing the functional demands of your specific application. High-traffic commercial kitchens or food service areas demand quartz artificial marble formulations offering maximum scratch and stain resistance despite premium pricing. Residential kitchen countertops in moderate-use households can utilize mid-grade engineering marble balancing performance and cost. Bathroom applications where moisture resistance outweighs impact concerns may utilize cultured marble's economical seamless installations.

Consider heat exposure patterns—kitchens with serious home chefs who frequently use cast iron cookware or transfer pans directly from stovetops might better suit natural stone's superior heat resistance despite other practical disadvantages. Conversely, households using trivets as standard practice gain little benefit from natural stone's thermal properties while sacrificing artificial marble's maintenance advantages.

Evaluate existing installation conditions including substrate quality, structural loading capacity, and access constraints. Renovation projects with limited structural support benefit from artificial marble's reduced weight. Difficult access situations favor lighter materials that simplify transport and handling. Projects requiring curved surfaces or integrated features may find artificial marble's moldability enables designs impossible with natural stone fabrication.

Color Selection and Design Coordination

Artificial marble's color customization capabilities enable precise matching to broader design palettes. Light brown artificial marble options coordinate with warm wood tones and earth-based color schemes popular in transitional and rustic contemporary designs. Light beige variations provide neutral backgrounds that complement diverse cabinet colors and hardware finishes.

Request physical samples rather than relying on photographs or renderings—artificial marble's appearance varies significantly under different lighting conditions, and digital images rarely accurately represent actual color and pattern. Evaluate samples in the actual installation location under both natural daylight and artificial lighting conditions that will illuminate the finished installation. Consider how surrounding materials including cabinetry, flooring, and wall colors interact with the marble selection.

For large projects requiring multiple slabs, confirm that supplier can provide consistent material from single production batch. Request written confirmation of batch numbers and reserve adequate material to cover installation plus 15% overage for cutting waste, future repairs, or potential remodeling. Inconsistent batches can create visible color or pattern variations that compromise installation appearance.

Budget Considerations and Value Analysis

Develop comprehensive cost comparisons including material, fabrication, installation, and projected maintenance expenses over expected service life. Initial material cost represents only 40-50% of total installed cost—fabrication complexity, edge detail selections, and installation challenges significantly impact final project costs. Request itemized quotes breaking down material, fabrication, delivery, and installation charges to enable accurate vendor comparisons.

Factor long-term value including maintenance cost avoidance and expected replacement timeline. Natural marble's lower annual maintenance costs—eliminating professional sealing services worth $200-400 annually—offset higher initial investment over 15-year lifecycle. Projects with tight upfront budgets but flexible operating budgets may favor premium materials with lower lifecycle costs, while build-to-sell developers optimize initial costs prioritizing attractive appearance over long-term maintenance efficiency.

Consider warranty coverage and manufacturer reputation—quality producers back products with 10-15 year limited warranties covering manufacturing defects, while budget suppliers may offer minimal or no warranty protection. Warranty terms reveal manufacturer confidence in product durability and provide recourse if premature failure occurs. Research supplier reputation through industry associations, third-party reviews, and references from completed projects.

Supplier Evaluation and Selection

Assess potential suppliers based on multiple criteria beyond price quotations. Evaluate production capabilities including available colors, custom formulation options, and lead times for standard versus custom products. Suppliers offering comprehensive stone solutions alongside artificial marble provide flexibility for projects combining multiple material types, simplifying procurement and coordination.

Request technical specifications including composition details, density measurements, absorption rates, and relevant certifications. Quality manufacturers provide detailed technical data sheets documenting material properties and performance test results from independent laboratories. Verify compliance with applicable standards including NSF/ANSI 51 for food contact surfaces in commercial applications or regional building code requirements.

Evaluate supplier service capabilities including fabrication support, installation guidance, and post-installation support. Suppliers providing technical assistance during design development help avoid specification errors that cause installation problems. Access to experienced fabrication partners familiar with specific material handling requirements prevents damage during cutting, edge profiling, and installation phases.

Installation Requirements and Professional Services

Artificial marble fabrication and installation requires specialized skills and equipment ensuring proper handling and lasting performance. Professional fabricators possess calibrated cutting equipment, diamond tooling, and polishing systems achieving precise cuts and finished edges matching factory quality. DIY installation risks material damage, improper seaming, and voided warranties.

Verify installer certifications and experience with specific material types—techniques optimized for natural stone may not translate directly to artificial marble installation. Request references from recent projects using similar materials and inspect completed installations evaluating seam quality, edge finish, and overall craftsmanship. Poor installation undermines even premium material quality, creating failure points and appearance issues that disappoint clients and generate costly callbacks.

Confirm installation timeline and coordination requirements including template scheduling, fabrication duration, and installation windows. Most projects require 2-4 weeks from template to installation depending on material availability and fabrication complexity. Complex installations with multiple seams, intricate cutouts, or custom edge details extend fabrication time. Coordinate installation with other trades including plumbers installing undermount sinks and electricians positioning electrical outlets to prevent schedule conflicts.

Conclusion

Artificial marble represents a sophisticated engineered alternative delivering marble's aesthetic appeal with enhanced practical performance. The material's non-porous composition, consistent appearance, and reduced maintenance requirements address many limitations that complicate natural marble ownership, particularly in moisture-prone environments and high-use applications. Understanding the composition variations—from premium quartz artificial marble to economical cultured marble formulations—enables selecting products matching specific performance requirements and budget parameters.

The decision between artificial and natural marble ultimately depends on prioritizing competing values. Projects emphasizing maintenance-free longevity, budget predictability, and consistent appearance favor engineered alternatives. Installations where natural material authenticity, unique character, and superior heat resistance justify premium costs and ongoing maintenance lean toward quarried stone. Many discerning design professionals strategically combine both material types throughout comprehensive projects, deploying each where its specific advantages provide maximum value.

Whether you're specifying materials for luxury residential developments, hospitality properties, or commercial installations, artificial marble merits serious evaluation alongside natural stone alternatives. The material's evolution from basic cultured marble to sophisticated engineered stone products positions it as a legitimate choice for discriminating clients who previously considered only natural materials. As manufacturing techniques advance and custom color capabilities expand, artificial marble increasingly competes on aesthetic grounds while maintaining decisive practical advantages.

Ready to explore how artificial marble can enhance your next project? Browse our comprehensive artificial marble collection featuring customizable colors, finishes, and applications. Our technical team provides specification support, material samples, and project consultation ensuring optimal material selection for your unique requirements. Contact Future Stone Group to discuss how our global sourcing capabilities and fabrication expertise deliver luxury surface solutions combining timeless elegance with modern performance.